Industrial Module – Reliable, High-Performance Water Treatment Solution

Our Industrial Module is designed to meet the rigorous demands of large-scale water and wastewater treatment applications. Built using high-quality materials like PES and PVDF, this system ensures long-lasting durability and stable operation across a wide range of conditions. The module features inside-out and outside-in filtration options and supports various configurations, offering flexibility for industrial environments.

With superior resistance to chlorine and temperature variations, it effectively handles high turbidity levels and delivers excellent permeate flux. The module is engineered for easy integration into cross-flow or dead-end systems and supports automatic backwash, chemical cleaning, and low maintenance cycles. Its membrane pore size of 0.03μm ensures high precision in separating contaminants, making it ideal for industrial processes requiring clean, reliable output.

From chemical plants to municipal water facilities, this module is a trusted solution for efficient, sustainable, and cost-effective filtration.

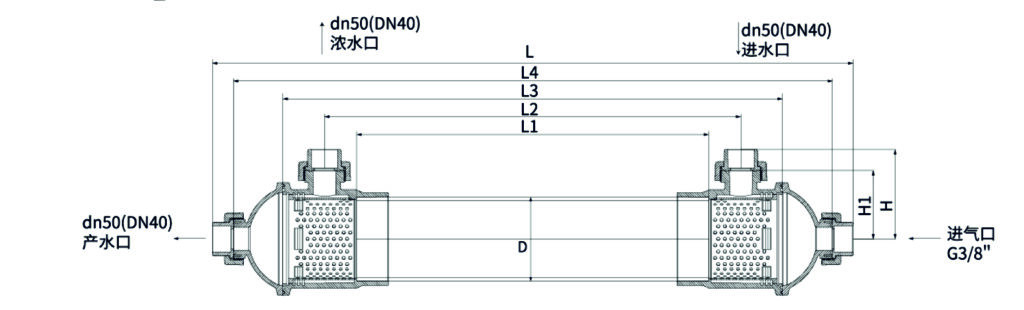

Model MP4060

| Model | D | L | L1 | L2 | L3 | L4 | H | H1 |

|---|---|---|---|---|---|---|---|---|

| MP4060 | 90 | 1124 | 894 | 925 | 1000 | 1070 | 110.5 | 83.5 |

Specification Of MP4060 –

| ITEM | MP-4060 |

|---|---|

| Membrane area | 6m² |

| Membrane material | PVDF |

| End seal material | Epoxy Resin/Polyurethane Resin |

| Filter method | Full volume or cross – flow filitration |

| Nominal cut Molecular Weight (Dalton) | 6000-150000 |

| Maximum Water inlet pressur | 0.6MPa |

| Maximum transmembrane pressur difference | 0.15MPa |

| Maximum backwash pressure | 0.25MPa |

| Design flux | 40~120LMH |

| Influent ph value | 2~11 |

| Operating temperature | 5°C~45°C |

| Production water turbidity | <0.01 NTU |

| Pollution Density Index (SDI) | < 2.5 |

| Escherichia coli removal rtae (log) | > 6 |

| Virus removal rate (log) | > 6 |

| Conventional membrane water requirements | Turbidity15NTU (in the use of surface water, River water, well water and other water source should be increased Surce should be increased Prwtreatment, it is recommended to increase the security below 100um filter or disc filter.) |

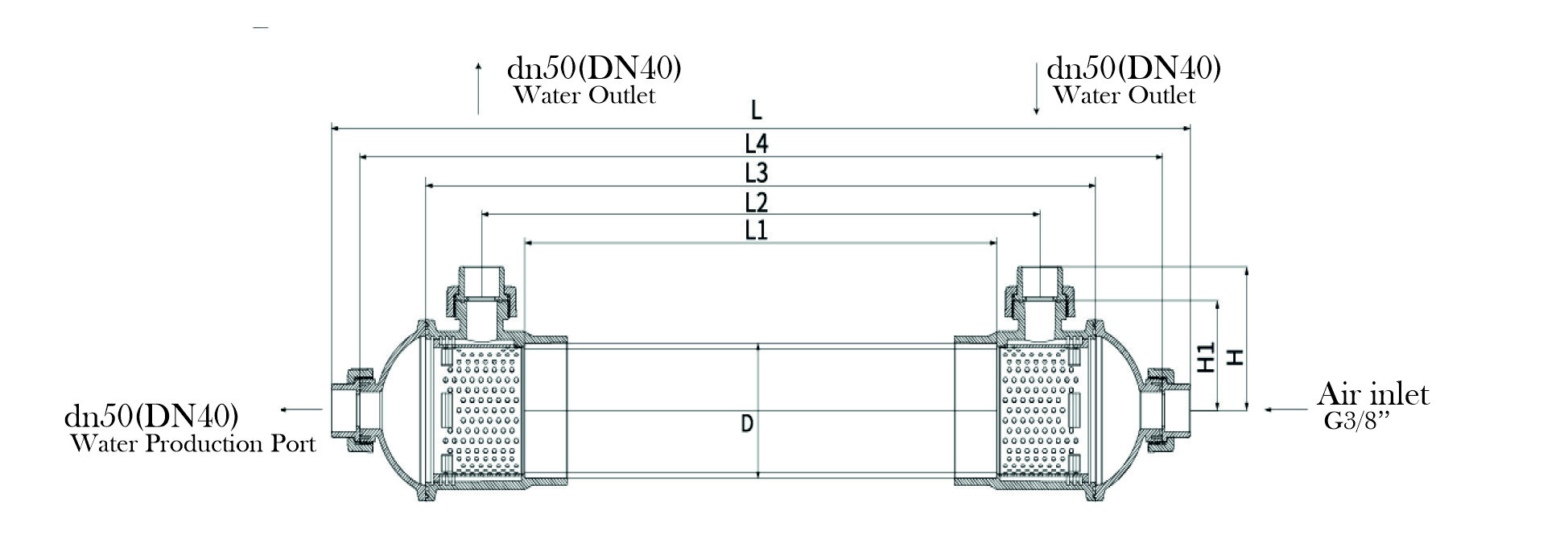

Model MP6060

| Model | D | L | L1 | L2 | L3 | L4 | H | H1 |

|---|---|---|---|---|---|---|---|---|

| MP6060 | 160 | 1813 | 1265 | 1387 | 1545 | 1733 | 170 | 130 |

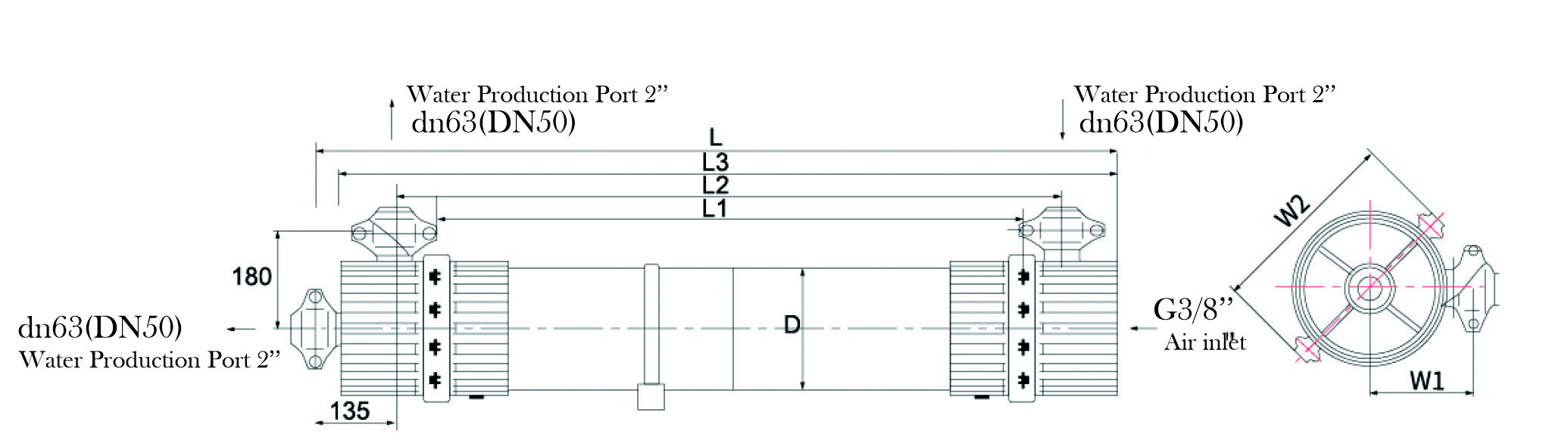

Models MP2860 & MP2880

| Model | D | L | L1 | L2 | L3 | W1 | W2 |

|---|---|---|---|---|---|---|---|

| MP2860 | 225 | 1860 | 1500 | 1630 | 1820 | 180 | 342 |

| MP2880 | 225 | 2360 | 2000 | 2130 | 2320 | 180 | 342 |

Specification about MP2660 & MP2880

| ITEM | MP-2860 | MP-2880 |

|---|---|---|

| Membrane area | 53m² | 77m² |

| Membrane material | PVDF | PVDF |

| End seal material | Epoxy Resin/Polyurethane Resin | Epoxy Resin/Polyurethane Resin |

| Filter method | Full volume or cross – flow filitration | Full volume or cross – flow filitration |

| Nominal cut Molecular Weight (Dalton) | 6000-150000 | 6000-150000 |

| Maximum Water inlet pressur | 0.6MPa | 0.6MPa |

| Maximum transmembrane pressur difference | 0.15MPa | 0.15MPa |

| Maximum backwash pressure | 0.25MPa | 0.25MPa |

| Design flux | 40~120LMH | 40~120LMΗ |

| Influent ph value | 2-11 | 2~11 |

| Operating temperature | 5°C~45°C | 5°C-45°C |

| Production water turbidity | ≤0.01 NTU | ≤0.01 NTU |

| Pollution Density Index (SDI) | < 2.5 | < 2.5 |

| Escherichia coli removal rtae (log) | > 6 | > 6 |

| Virus removal rate (log) | > 6 | > 6 |

| Conventional membrane water requirements | Turbidity 15NTU (in the use of surface water, River water, well water and other water source should be increased Surce should be increased Prwtreatment, it is recommended to increase the security below 100um filter or disc filter.) | Turbidity 15NTU (in the use of surface water, River water, well water and other water source should be increased Surce should be increased Prwtreatment, it is recommended to increase the security below 100um filter or disc filter.) |

UF Module Cleaning Process

Pre-Cleaning Steps

- Shutdown and depressurization: Shut down the UF system and depressurize the module.

- Drainage: Drain the module and associated piping.

- Pre-cleaning flush: Perform a pre-cleaning flush with clean water to remove any loose debris.

Chemical Cleaning

- Chemical selection: Select a cleaning chemical compatible with the module and membrane materials.

- Chemical preparation: Prepare the cleaning solution according to the manufacturer’s instructions.

- Cleaning cycle: Circulate the cleaning solution through the module for a specified time (typically 30 minutes to 1 hour).

- Rinsing: Rinse the module with clean water to remove residual cleaning solution.

Physical Cleaning

- Backwashing: Perform a backwash cycle to remove any remaining debris.

- Forward flushing: Perform a forward flush cycle to remove any remaining debris.

- Vibration: Apply mechanical vibrations to the module to dislodge any remaining debris.

vivektank –

Best